It’s time to talk about two similar terms causing a lot of confusion in the workplace when it comes to outfitting workers in the appropriate visibility workwear.

We’re talking about reflective and retroreflective tape.

Reflective vs. Retroreflective

What exactly is the difference between these two? The biggest clue is the word “retro” which helps us to know and understand the difference between these two reflective surfaces.

When you think of reflective, think of a mirror. Where a retroreflective surface is like the reflector you would find on something simple, like a bike reflector. To understand what “Retro” is, let’s look at a definition: “…denoting action that is directed backward.”

Regarding reflective tape, it is defined as returning the light back to where it originally came from.

What does reflective mean?

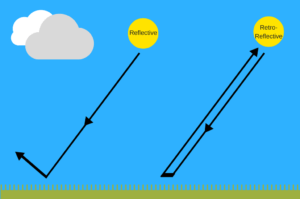

So let’s come back to our mirror example for a moment. The mirror is reflective, as it sends light out in different directions, depending on the angle of entrance. With high visibility clothing, this wouldn’t be a good use for protecting workers.

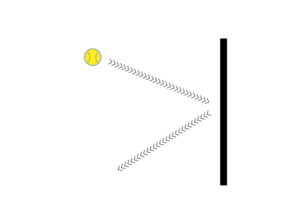

To explain this a little bit better, if you think back to when you were a kid and threw a ball against the wall. The ball would bounce back, but at an angle opposite of what it came to the wall. See the example below:

What does retroreflective mean?

Now, in the instance of retroreflective, light travels in and back out, to and from the same point.

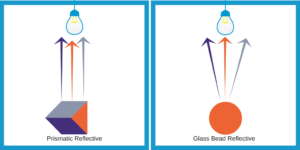

There are two basic types of retroreflective surfaces: glass bead surfaces and prismatic surfaces and both reflect light differently.

Glass bead reflective surfaces use glass spheres to collect light and bounce it back to the source. The rounded shape of the beads is what creates the retro reflectivity.

Prismatic reflective surfaces do the same thing but with sharp angles like prisms. They work like the glass beads but are more efficient, thus creating a brighter return of light.

Retroreflective tape for high visibility apparel

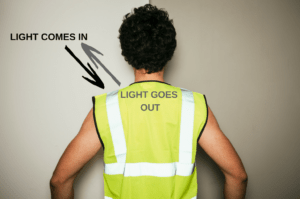

High visibility apparel is made to stand out in various environment. This helps to keep the user seen, and ultimately safe, from various moving vehicles, especially in low-light situations. High visibility apparel gets retro-reflective taping placed on the garments and helps to enhance visibility in low-lighting.

As the light hits the retroreflective taping, it redirects the light back to its original source. The retroreflective tape enhances visibility much better than standard reflective tape, due to dispersing the light better than that of the reflective tape.

Retroreflective requirements for Ansi 107

Retroreflective tape is a vital part of any high visibility garment and is a requirement if you need to be ANSI 107 compliant.

One such requirement states that the retroreflective tape needs to be an appropriate width for the garment class that it falls under. There also should be an appropriate distance between the vertical and horizontal bands that are placed on the torso, sleeves, and trousers.

All class 1 and 2 shoulder areas should have at least 23.25 square inches of reflective material in the shoulder area. Class 3 garments must always have reflective on the sleeves and in this case, shoulder area reflective is optional.

When it comes to high traffic areas and safety, high visibility apparel and retroreflective taping will ensure you are seen and raise your safety to the next level.

Topics: Visibility

.png?width=621&height=373&name=Model-Apparel%20Logo%20File%20from%20Ian%20(1.2).png)

.png)