When talking about high-visibility clothing and the rules your company should follow, you may have heard of the term ANSI 107.

The question is, does your company work in an industry that must follow this rule? Or maybe it's the step you take to protect your employees more?

In this article, you will learn about the American National Standards Institute (ANSI). You will also learn how ANSI 107 started and where it is now.

What is ANSI (American National Standards Institute)?

For more than 90 years, the American National Standards Institute has been serving as the U.S. private sector voluntary standardization system. 5 engineering groups and 3 government agencies started the group. Now, it is a private nonprofit group that only has members.

ANSI is supported by many private and public organizations. Its goal is to make US businesses more competitive around the world and make life better for Americans. It does this by promoting and helping to create voluntary consensus standards, conformity assessment systems, and promoting their integrity.

What is ANSI 107 and why is it important?

The ANSI/ISEA 107 standard was first established in 1999, as 107-1999. ANSI 107-1999 was the first standard for the design of high visibility safety apparel. It wasn’t until late 2008, when the first U.S. Federal regulation (23 CFR, part 634) was implemented for Federal Aid highway environments and required the use of performance, Class 2 or 3 ANSI/ISEA 107 garments. The 23 CFR rule applies to highway construction, maintenance, and utility workers.

What changes happened with ANSI 107-2010?

ANSI 107-2010 is a standard for construction, emergency responders, utility, airport ramp personnel, and any other workers who regularly work in low visibility areas while on the job. ANSI 107-2010 provided guidelines for the selection and use of high-visibility safety apparel such as shirts, rainwear, safety vests, outerwear, and headwear to improve worker visibility during the day, in low-light conditions, and at night. ANSI 107-2010 brought new changes from the previous iteration, which included:

- Retroreflective material in the shoulder area.

- Clarification of the definitions of waterproof, water resistant, and water repellant.

- New labeling and test requirements for flame resistant clothing.

ANSI 107-2010 Specifications

ANSI 107-2010 changes covered design, care labeling, requirements for background and combined-performance retroreflective materials, and photometric and physical performance requirements for retroreflective materials.

Design

The ANSI 107-2010 standard provided design guidelines and specified the photometric requirements, minimum amounts of component materials, colors, and placement to create garments and headwear that enhance the visibility of workers.

Component Colors

There are three different colors for background and combined-performance material from which to choose: fluorescent yellow-green, fluorescent orange-red, fluorescent red.

Care Labeling

It’s only after all materials have been tested against performance requirements and certificates of compliance from a third-party testing laboratory have been issued, then the apparel manufacturers then assemble garments according to the design guidelines in ANSI 107-2010, Section 6. Only after all the materials’ performance and design requirements have been met, can a garment be labeled ANSI/ISEA 107-2010 compliant. To understand more about garment labeling, general marking, and instructions, see Sections 10 and 12 of the standard.

Requirements for background and combined-performance materials

In Section 7 of the standard, we see specifications for color, brightness, fabric strength, and moisture resistance after various exposure tests. If a garment is intended to provide protection during rainfall, background materials also need to be tested as water repellent, water resistant, and/or water-proof. Background and combined-performance materials need to be tested for color and brightness when new. They should also be tested for colorfastness after washing and exposure to Xenon (UV light). The background materials must also be tested for colorfastness after crocking and perspiration tests.

Retroreflective material placement

Class 1 and 2 garments, such as vests and T-shirts, and Class 3 garment designs, such as vests with Class E pants ensembles, coveralls, outerwear, and rainwear should achieve:

- Use of retroreflective band widths suitable for the garment class. (See Section 6.1.1. of the standard)

- Provides complete 360 degree visibility with horizontal gaps of 50mm or less.

- Garments without reflective material encircling the sleeves are now required to have 150cm2 (23.25 in2) of reflective material in the shoulder area, to provide 1800 visibility of the wearer.

- Proper separation distances of vertical and horizontal bands placed on the torso, sleeves, and trouser areas.

- Proper retroreflective band placement and garment design.

- In addition to trim, retroreflective patterns, such as logos, design icons, or identification text may contribute to the maximum area requirements specified in Table 1.

Photometric and physical performance requirements for retroreflective and combined-performance materials

Section 8 of the standard says what the light and performance standards are for retroreflective and combined-performance materials. These standards include minimum brightness after test exposure.

- Retroreflective and combined-performance materials are certified to ANSI/ISEA 107-2010 specifications.

- All material must meet the minimum brightness requirements after tests for abrasion resistance, flexing, folding at cold temps, variations in temps, influence of rainfall, and laundering. When washing is indicated on the care label, the number of cycles should be tested per ISO 6330 Method 2A, 600c, or dry-cleaning per ISO 3759.

- Combined-performance material must almost meet the minimum luminance or brightness factors after a Xenon exposure test (UV light).

What changes happened with ANSI 107-2015?

The ANSI standard is being revised roughly every 5 years, with the previous revision coming in 2010. This latest edition (ANSI/ISEA 107-2015) was released on February 1, 2016.

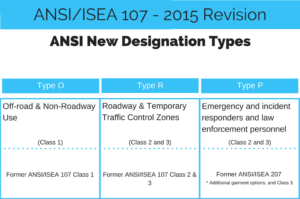

The new ANSI standard brought new type designations, replacing the existing classes.

So which type ANSI 107 garment do you choose?

- Type O – is for use off-road and on roads (Class 1) and is for mining, oil, and gas industries. It does not need to meet a standard.

- Type R – is for roadway and temporary traffic control zones (Class 2 & 3) and targets those who work on public roadways, construction and are required to comply with MUTCD (Manual on Uniform Traffic Control Devices).

- Type P – is for emergency, incident responders, and law enforcement personnel (Class 2 & 3). Type P targets law enforcement, fire departments, and first responders.

Logos, lettering, and ID panels

If you want to add a logo, an ID panel, or lettering, it can cover up to 72 in.2 of the minimum amount of background material and 22in.2 of the minimum amount of retroreflective material. There can also be no gaps in the retroreflective material greater than 1.97” horizontally.

Class 1 and 2 shoulder area requirements

If class 1 and 2 garments (all types) do not have reflective encircling the sleeves, then they must:

- Have at least 23.25 in.2 of reflective material in the shoulder area.

- Shoulder area is 5.9” down from the shoulder high point (total front to back).

- Class 3 garments must always have reflective on the sleeves, so shoulder area reflective is optional.

Smaller size allowance

This only applies to Type R garments only and there can be no deduction in retroreflective allowed. All large sizes must meet the regular minimum requirements. For class 2, the smallest size in the size range may have a minimum of 540 in.2 of background material. While the class 3 smallest size in the size range may have minimum of 1,000 in.2 of background material.

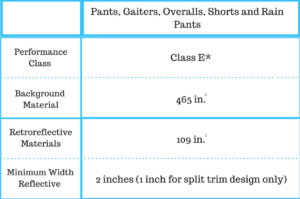

ANSI/ISEA 107 Garment Class E

Class E garments do not meet ANSI/ISEA 107-2015 when worn alone. They can be worn with class 2 garments, to make class 3. A pair of gaiters can now be certified class E. If you would like to learn more and purchase the ANSI 107-2015 standard, then you can purchase directly from the ANSI website.

What changes happened with ANSI 107-2020?

As mentioned, updates to ANSI 107 take place every 5 years or so. As expected, there was a release of updates in 2020, with more expected later in 2025.

The changes include:

- Removing the criteria for high-visibility accessories. The focus is instead on the configurations and design requirements that contribute to the Type-Performance Class designation.

- Adding accommodating situations since garments can become soiled easily because of the work environment. This edition has specific rules for a single-use disposable coverall. It must meet the minimum material amounts and color requirements for all HVSA products that are compliant. It also emphasizes that the material integrity requirements are only for single-use disposable coveralls, for which special marking is used.

- The tests methods have been changed to match other material integrity tests better. They also recognize the current versions used to evaluate the materials.

- Introducing the concept of measuring the overall nighttime luminance of a garment by including optional language that allows a manufacturer to test a garment according to ASTM E1501.

If you want more information about high-visibility clothing for your team, contact us. We can help you choose the right clothes for your team and meet your safety standards.

Topics: Visibility

.png?width=621&height=373&name=Model-Apparel%20Logo%20File%20from%20Ian%20(1.2).png)

.png)